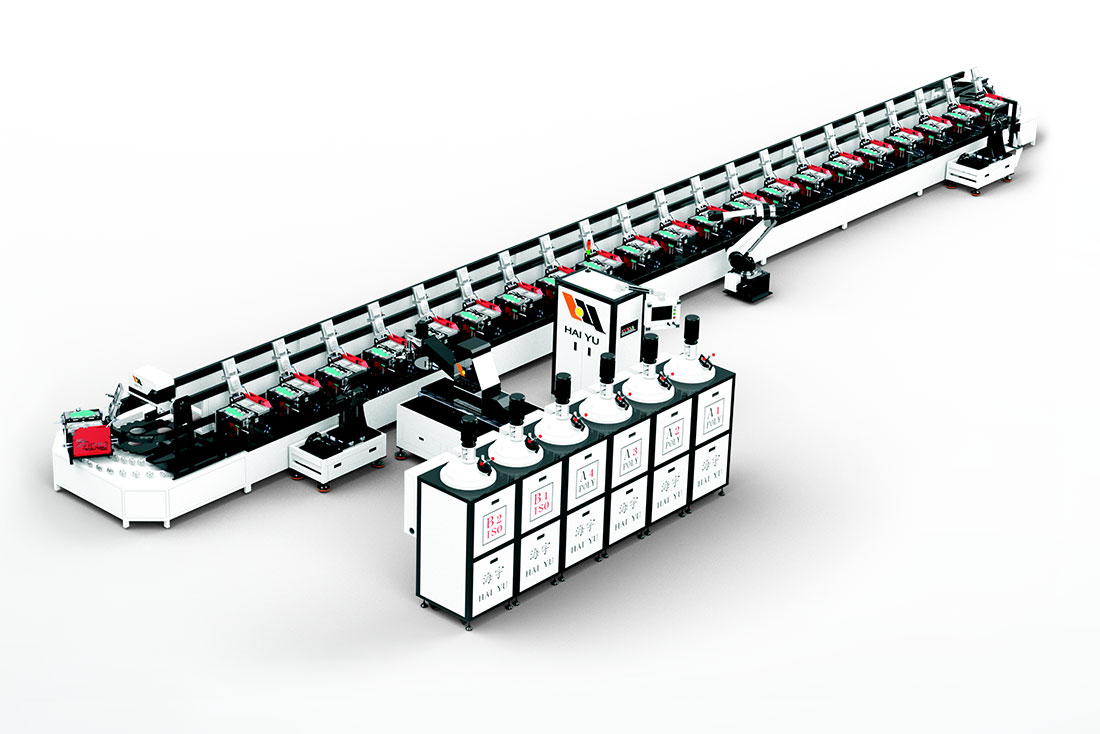

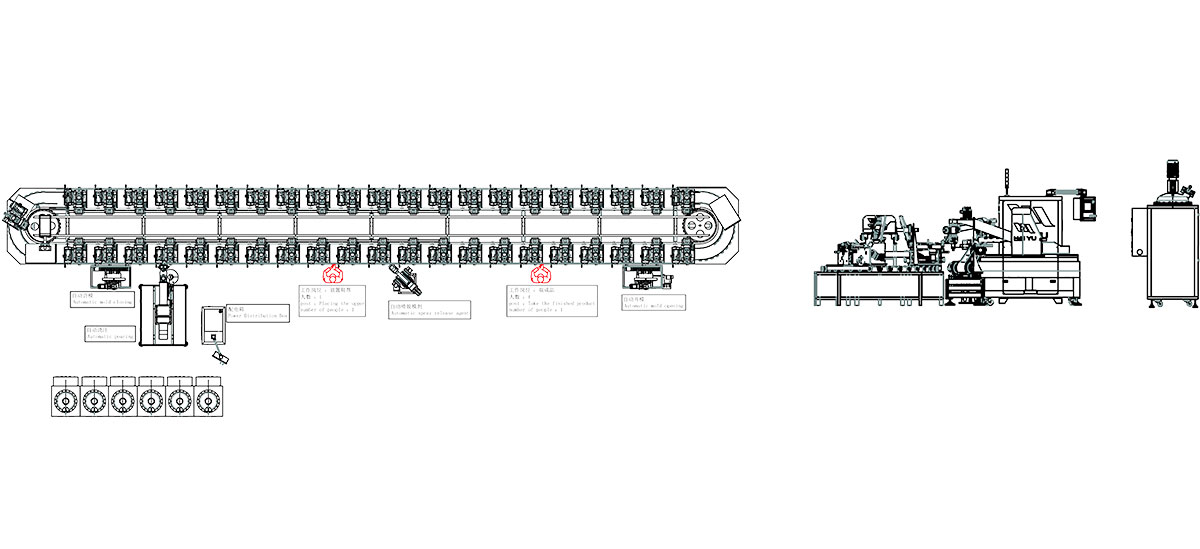

Fully Automatic Polyurethane Pouring Machine With Auxiliary Tooling HY-LP4I2-120A

性能特点

PRODUCT GENERALIZATIONS

With a variety of injection protection, automatic monitoring of the metering pump working status, etc., when Kobe For example, the number of pump revolutions, material temperature, once the pressure is abnormal, stop the injection to prevent waste.After the system controller inputs the programming, the assembly line, pouring, demoulding, clamping and other components are fully automatic.Intelligent operation, no manual operation, high positioning accuracy, smooth operation and simple operation.Rotation speed of stirring n=9400r/min.The materials evenly mixed to produce

delicate products with better elasticity;

If equipped with external coloring device,it can manufacture polyurethane products of varity of colors;

delicate products with better elasticity;

If equipped with external coloring device,it can manufacture polyurethane products of varity of colors;

机械部件

PRODUCT GENERALIZATIONS

技术参数

TECHNICAL PARAMETER

| Model | HY-FP4I2-120A |

| Max. travel speed | X,Y=60m/min,Z=24m/min |

| Work area | X,Y,Z=380.600.100 |

| Raw Material Quantity | 6 |

| Tank Volume | 120 |

| L/R Output of Flow Control Pump | 20 |

| Flow Control pump Quantity | 6 |

| Ratation Speed of Flow Control Pump(r/min) | 60-280 |

| Measuring precision | 0.5 |

| R/MIN Ratation Speed of Pouring Head Mixer | 9400 |

| Cleaning Type of Pouring Head | auto |

|

Total Times of Continuous Pouring During Pouring Head Cleaning Period (times) |

>80 |

| Max. output Volume | 130 |

| Work digits | 60/80 |

| Characteristic of Product | Four Density Four Colors |

| Electrical supply | 400V 30-45A/50HZ |

| Total Power | 40KW |